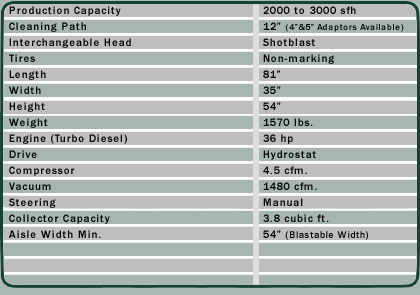

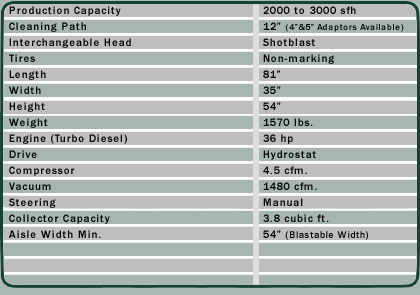

BW Manufacturing SCB-1200 Shot Blaster w/ Blast Head

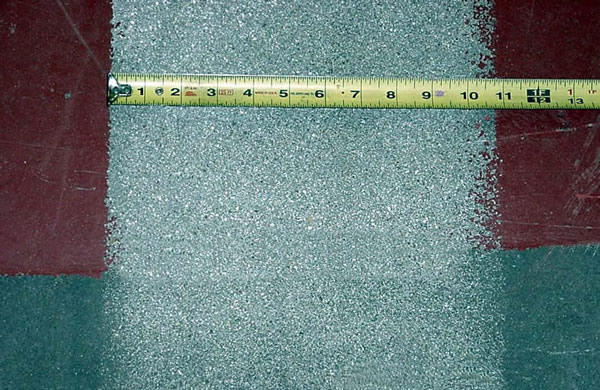

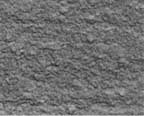

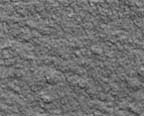

The SCB-1200 features a removable dust containment box with wheels for ease of dumping. One handed operation controls for raising and lowering heads, speed and shot control. A state of the art blast head design allowing you quick blast wheel changes and a feathered blasting edge, which enables each successive path to overlap without excessive penetration omitting the "striping effect". The finished surface is ideal for thin-set applications or for use with clear coatings along with the power to give you an aggressive shot blast profile when needed. The SCB 1200 comes equipped with the B-1200 Blast Head. The optional accessory attachments are the SC-1200 Scarifying Head and the DG-1225 Diamond Grinding Head complete with diamonds.

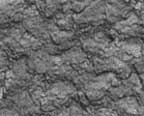

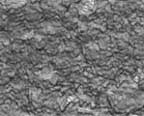

After years of research, development and testing, B W Manufacturing, Inc. has produced the only mid-sized ride on shotblast/scarifying machine in the market today. The SCB-1200 gives you mobility and versatility by being able to switch back and forth between blasting, scarifying, and diamond grinding/polishing in just minutes.

The SCB-1200 features a removable dust containment box with wheels for ease of dumping. One handed operation controls for raising and lowering heads, speed and shot control. A state of the art blast head design allowing you quick blast wheel changes and a feathered blasting edge, which enables each successive path to overlap without excessive penetration omitting the "striping effect". The finished surface is ideal for thin-set applications or for use with clear coatings along with the power to give you an aggressive shot blast profile when needed.

Using the latest technology in EPA approved liquid cooled diesel engines and catalytic converter; you are far below any minimal emissions standards. With the use of state of the art components, compressors, electronic pulsation, hydraulics, and drives, the SCB-1200 is the most reliable and productive mid-sized surface preparation machine on the market today.

VIEW IN OUR STORE

VIEW IN OUR STORE